Feature

The Process of Manufacturing

Metal Crafts

Tithi Tahmina Khan

THE hand-made Metal Craft of Bangladesh has developed its industry mainly in Dhamrai reserving the traditional craftsmanship alive for years. The article is written after an exploration to the place.

We got down at the last bust stop of Dhamrai named Dullibhita, rented a van and started for the RothMela Bazaar where the handmade metal craft industry is located. Every year the largest RothMela, a traditional Hindu festival of Bangladesh takes place there. We found last years colourful Roth there and the next year's one in progress.

The van crossed the Bazaar and was going through the town street. Running through the pleasant surroundings of an old town, we stopped in front of a Metal Workshop.

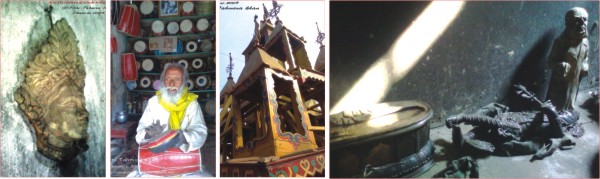

The outlook of the workshop is like an aged palace or Jamidarbari. We went inside and found out that it was both a workshop and the home of the owner. The artists and workers were working inside the workshop, an old woman and a Purohit preparing for Puja at one side of the home yard. The metal crafts range from everyday use metal crocks to decoration pieces to religious idols for both Buddhism and Hinduism.

According to the metal craft artists in Dhamrai the metal crafts in Bangladesh are manufactured by hand in two ways- lost wax process and hollow process.

The lost wax process is used for manufacturing small crafts as things made by lost wax process are solid bodied, not hollow inside. At first the structure of the object is made by wax. The process requires high skilled artists to make the tiny parts of the object after days and nights of work. Next a layer of clay of an inch is put over the wax object and left for some days allowing them to dry. When it finally dries a hole is made near the bottom of the object and it is put on fire. The clay gets burned and is made strong and the melted wax comes out of the hole. Later melted metal (bronze) is poured inside the structure through the hole. When the metal becomes hard, the outside clay layer is removed and the required metal object is ready for polish.

The hollow process is for manufacturing large structures. Objects made by this process are light in weight as the inside part remain hollow. The process is almost similar to the lost wax process. Another layer of wax is given over the object by the hollow process before putting it on fire. Then a layer of clay is given. So, the object contains two layers of wax and clay each. The structure is burned into fire and the two layers of wax come out. Next, the metal is put inside the two layers of clay which replaces the second layer of wax. And the first layer of wax remains as a hollow.

We found many old buildings, temples and shops around the place. We tried to go inside to take photographs and to collect information as much as possible. A shop for hand made musical instruments was there and the owner, an old man played us the Dhol. Time was short. So, we started for Dhaka making a wish to come back again day for more great experiences.

|